Details

Description

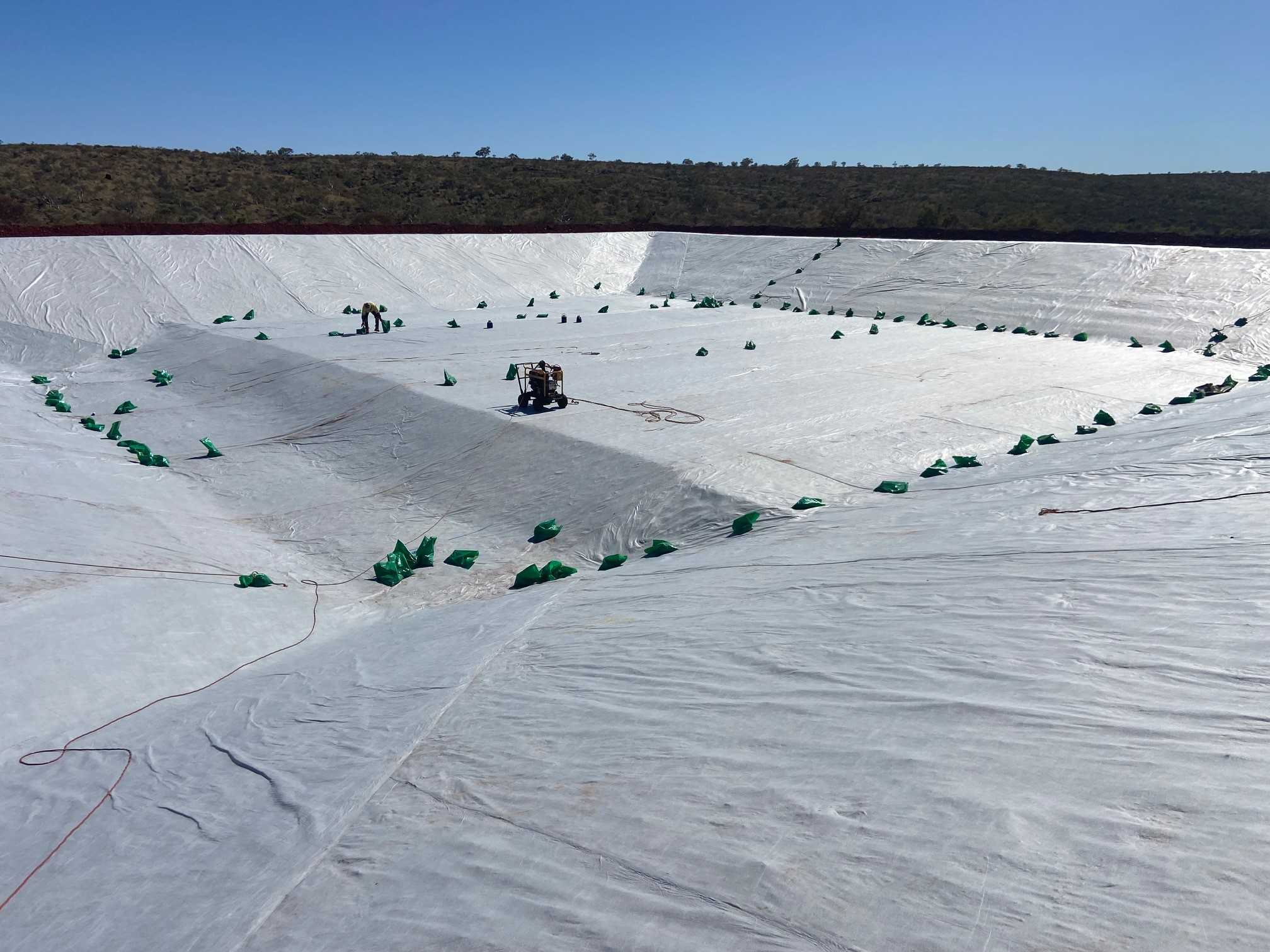

Fortescue’s Eliwana Mine Site required the installation of dewatering infrastructure to allow the mining of the Flying Fish ore body. This included a new bore field, pipeline infrastructure, holding tanks and turkey’s nests.

TCD’s key deliverables included:

- 45km of HDPE pipelines for water supply of the mine, inclusive of 8km of buried pipelines

- 4 x Turkey’s Nests, each with a LV and HV Standpipe

- 1 x Transfer Pond and Pump Station

- 12 x Abstraction Bores

- 6 x Re-Injection Bores

Whilst on-site additional works were awarded for the pipe re-alignment for the Flying Fish Haul Road, as the current design clashed with the existing pipeline. Works included the installation and re-alignment of piping, valves and fittings.

Summary

$18M

Total Project Value

Client

Location

Project Duration

Project Start

Project Finish

Gallery

Talk to our Construction Experts

We support our clients when they need it most. Contact our experts to see how Aaro can partner with your business.